When a new light source enters the market, the stroboscopic problem also surfaced. PNNL's Miller I said: The amplitude of the light output of the LED is even greater than that of an incandescent lamp or a fluorescent lamp. However, unlike HID or fluorescent lamps, solid-state lighting SSL is a DC device, which means that when a constant current is supplied, the LED can be lit without flicker.

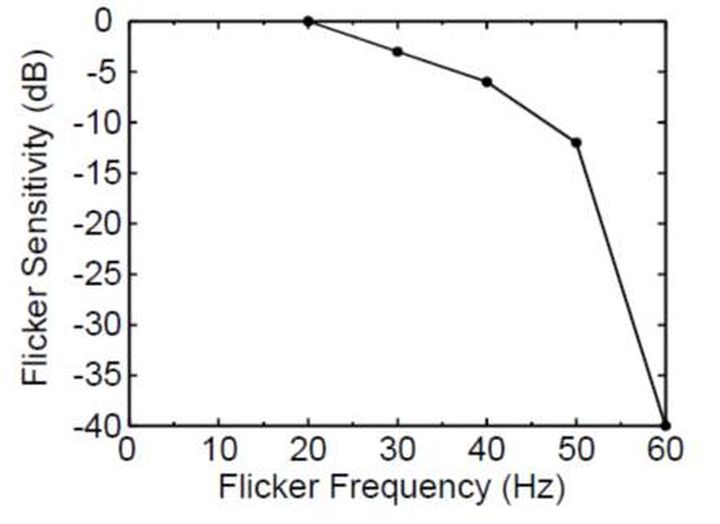

For those simple LED circuits that do not use a separate constant current adjustment drive, the brightness of the LED will change with the alternating current cycle. The drive plays two roles, power supply and rectification. The conversion process from driving to LED, alternating current to direct current will produce voltage and current output ripples. This kind of ripple exists at twice the frequency of the supply voltage, which is 120H in the United States. There is a corresponding relationship between the output of the LED and the output waveform of the drive. Dimming is another cause of flicker. Traditional dimmers, such as TRIAC dimmers (an electronic component that can conduct two-way conduction), adjust the current and reduce the light output by extending the shutdown time during the switching cycle. For LEDs, it is ideal to use pulse width modulation (PWM) to switch LEDs at frequencies exceeding 200 Hz. However, Benya emphasized: "If you use pulse width modulation at a very low frequency, such as the normal power supply frequency, it will cause very high flicker."

Common sense analysis of LED stroboscopic:

There are four possibilities to cause the LED light source to flicker or turn on and off.

1) The ED lamp bead does not match the LED driving power supply, and the normal single 1W bead withstands current: 280-30mA.

Voltage: 3.0-3.4V, if the lamp chip is not of sufficient power, it will cause the light source to flicker, and the current is too high.

When it is received, it will turn on and off. In serious cases, the gold wire or copper wire built into the lamp bead will be burnt, causing the lamp bead to not light up.

2) It may be that the driving power supply is broken, as long as it is replaced with another good driving power supply, it will not flash

3) If the driver has an over-temperature protection function, and the material's heat dissipation performance of the lamp cannot meet the requirements, the driver's over-temperature protection starts

There will be a flashing and flashing phenomenon when working, for example: 20W floodlight housing is used to assemble 30W lamps, no heat dissipation work. It will be like this if done.

4) If the outdoor lamp also has the phenomenon of flashing on and off, then the lamp will be flooded and the result will be flashing and it will not turn on. The lamp beads and the driver will be broken. Just replace the light source.

How to reduce stroboscopic

The key to mitigating stroboscopic flicker is driving, which can be solved by providing a constant, non-oscillating current. However, manufacturers have to weigh other factors to drive cost, size, reliability and efficiency when supporting LED products. Ree is represented by Mark McClear, vice president of engineering. The intended use of the luminaire also needs to be considered to ensure that the product is not over-designed, because in some lighting situations stroboscopic flicker is acceptable, and some are not. Mcclear also said: "Manufacturers have been trying to optimize what products are suitable for what applications, and how to make strobe acceptable without increasing the cost." Capacitors can adjust the AC ripple from the driver to the LED, but it also has disadvantages, Benya said. Capacitors are bulky and sensitive to heat". Therefore, in a compact and limited space, such as LED replacement light source, the use of capacitors does not work. Using pulse width modulation (PWM) adjustable LEDs, manufacturers can adjust the current to very high frequencies exceeding several kilohertz. This is similar to electronic ballasts driving fluorescent lamps. But the higher the required frequency, the closer the distance between the driver and the LED. "Unfortunately, many people want to drive away from the lighting system, so it is not always feasible." Benya said. In order to simplify the compatibility test between dimmers and dimmable LED light engines (LED light engines), EMA (National Electrica/Manufacturers Association) released NEMA SSL7A-2013 "Solid State Lighting SSL Phase Cut Dimming: Basic Compatibility ", this is a guide for lighting product designers and manufacturers. As long as the dimmer and LED light engine meet the standard, they are compatible. Megan, NEMA's technical project manager, said that this standard is the first in the industry and signed by 24 major manufacturers. The goal of SSL7A is to get rid of the matching test of lamps and dimmers. What needs to be emphasized is that this standard only applies to technologies after the standard is released. As it said, the standard does not provide a method to "determine the compatibility of existing products or installed LED light engines and phase-cut dimmers".

Post time: Jan-05-2022