Ukukhipha ukushisa kwama-LED anamandla amakhulu

I-LED iyidivayisi ye-optoelectronic, kuphela u-15% ~ 25% wamandla kagesi azoguqulwa abe amandla okukhanya ngesikhathi sokusebenza kwawo, futhi amanye amandla kagesi cisheziguqulwa zibe amandla okushisa, okwenza izinga lokushisa le-LED libe phezulu. Kuma-LED anamandla amakhulu, ukuchithwa kokushisa kuyindaba enkulu edinga uphenyo olukhethekile. Isibonelo, uma ukusebenza kahle kokuguqulwa kwe-photoelectric kwe-LED emhlophe engu-10W kungu-20% njengoba kushiwo ngenhla, okungukuthi, u-8W wamandla kagesi aguqulelwa amandla okushisa. Uma kungekho zinyathelo zokukhipha ukushisa ezingeziwe, izinga lokushisa eliyinhloko le-LED enamandla amakhulu lizokhuphuka ngokushesha. Uma inani layo le-TJ Uma ukuphakama kudlula izinga lokushisa eliphezulu elivumelekile (imvamisa engu-150 ℃), i-LED enamandla amakhulu izolimala ngenxa yokushisa ngokweqile. Ngakho-ke, ekwakhiweni kwezibani zamandla aphezulu e-ED, umsebenzi wokuklama obaluleke kakhulu umklamo wokukhipha ukushisa.

Ukwengeza, ekubalweni kokushabalaliswa kokushisa kwamadivayisi kagesi ajwayelekile (njengamandla kagesi angu-1C), inqobo nje uma izinga lokushisa lokuhlangana lingaphansi kwezinga eliphezulu lokushisa elivumelekile le-junction (ngokuvamile li-125°C), kwanele. Kodwa edizayini yokulahla ukushisa kwe-LED enamandla amakhulu, imfuneko ye-TJ VALUE iphansi kakhulu kuno-125℃. Isizathu siwukuthi i-TJ inethonya elikhulu esilinganisweni sokukhishwa kokukhanya nempilo ye-LED: ukuphakama kwe-TJ, ukwehla kwezinga lokukhishwa kokukhanya kanye neminyaka yokuphila ye-LED ibe mfushane.

Indlela yokukhipha ukushisa yamandla aphezulu we-LED.

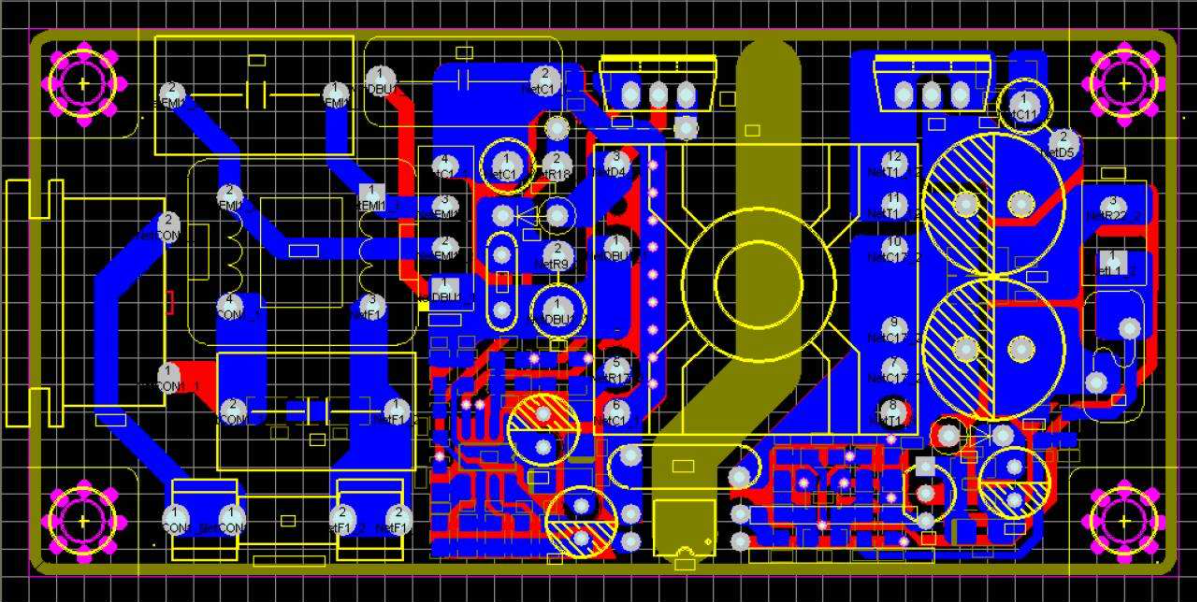

Ama-LED anamandla amakhulu anamathisela ukubaluleka okukhulu ekulahlekeni kokushisa ekwakhiweni kwesakhiwo. Abanye abaklami banephedi enkulu yensimbi yokukhipha ukushisa ngaphansi kwefasi, engenza ukushisa kwefa kusakazeke ngaphandle ngephedi yokukhipha ukushisa. Ama-LED anamandla amakhulu adayiswa ebhodini eliphrintiwe (PCB). Indawo engaphansi yephedi yokukhipha ukushisa ishiselwe nge-copper-clad surface ye-PCB, futhi ungqimba olukhulu lwe-copper-clad lusetshenziswa njengendawo yokukhipha ukushisa. Ukuze kuthuthukiswe ukusebenza kahle kokukhipha ukushisa, i-PCB enezingqimba ezimbili zethusi isetshenziswa. Lesi esinye sezakhiwo ezilula kakhulu zokulahla ukushisa.

Isikhathi sokuthumela: Mar-02-2022